Offering custom machining services since 1995.

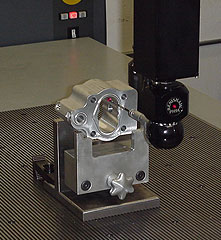

Mid-America Manufacturing (MAM) is proud to deliver support and professional manufacturing solutions to all of our customers. Our capabilities include precision machining, quality control processes, inspections, and much more.

Mid-America Manufacturing (MAM) is an ISO 9001:2015 certified job shop that prides itself on delivering support and solutions to the production challenges our customers experience every day.

Through years of experience in manufacturing, production management, process development, troubleshooting and tool & fixture design, we have earned a reputation for figuring out how to make tough parts.

The quality and precision of any prototype, production parts, jigs & fixtures depends on three key aspects:

⦁ The CNC and machining centers used to make the part

⦁ The knowledge and experience of the machine operator

⦁ Having a defined and approved Quality Management System (QMS) in place.

Over the years, Mid-America Manufacturing has and continues to invest in the latest machines, technology and training which allows us to meet the variety of demands from our customers. Our CNC Lathe capabilities along with the variety of CNC horizontal and vertical milling machine centers, including our CNC Bridgemill with a 165” x 79” capacity, provides the capacity and versatility to handle a wide range of machining needs for Brass, Aluminum, Alloy and even machinable plastic materials.

Understanding the ever-increasing demand for the highest standards for quality, Mid-America Manufacturing has established, documented, implemented, registered and maintains a Quality Management System and continually improves its effectiveness in accordance with the requirements of ISO 9001-2015. Certification was initially achieved in January 2005 with the following scope:

Design and development of precision machined products; including tooling, prototype, pilot runs and production runs.

The management team maintains a constant focus on promoting employee learning and building tools that allow us to better operate according to our Quality Policy:

As part of our QMS process, MAM performs three different types of inspections at different stages of the manufacturing process:

The machine operator performs various inspections of parts during or immediately after machining, using simple tools such as plug/pin gauges, inside mics, calipers and micrometers, to identify any variance from the specified tolerances.

In-process probing to verify key features and tolerances of a part to automatically monitor and adjust cutting tools during the machining process.

Inspection in our quality control (QC) department. MAM’s QC experts utilize height gages, microscopes, 2D projectors, micrometers, optical comparator machine (OCM) and coordinate measuring machines (CMM) to ensure that parts conform to the customers’ requirements.

Our ISO 9001:2015 certification was initially achieved in 2005 and we’ve kept it current ever since.

We take our materials seriously. We do not source materials from areas of conflict. Read more below.

Mid-America Manufacturing maintains Defense Logistics Agency (DLA) Central Contractor Registration (CCR) and certification according to the Joint Certification Program (JCP).

© Copyright Mid-America Manufacturing, LLC 2024. All Rights Reserved. | Privacy Policy

ISO 9001:2015 | Est. 1995

Web Design and Development by Saltech Systems

Offering custom machining services since 1995.