Offering custom machining services since 1995.

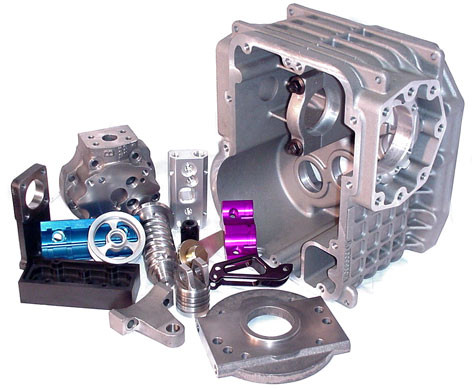

Mid-America is proud to offer many manufacturing services to our customers. See what Mid-America can do for you or your business below!

It doesn’t matter the size of the part or the intricate details of the design, MAM has the expertise and the machinery required to support your most demanding applications.

MAM has become a valuable resource for many when it comes to providing specialized machining services.

We’ve been designing & building parts for decades. Let our experienced designers and machinists help you bring your idea to life.

Added in 2015, our Hydrostatic Testing Process ensures your part is leak free, and ready for pressure-tight applications.

Improve overall product quality, by implementing our dry vacuum-pressure impregnation process. You can enhance the quality and durability of your parts, ultimately boosting customer satisfaction and reducing returns.

Choose a service from the options below. If you have questions or are ready to start a quote with our team, feel free to use the form at the bottom of the page to reach out to us.

It doesn’t matter the size of the part or the intricate details of the design, MAM has the expertise and the machinery required to support your most demanding applications.

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

Volume production machining is a large part of our daily focus providing our customers with a consistent flow of components to keep their manufacturing process running without interruption. But that’s not the whole story. Precision and accuracy are always maintained through the design and maintenance of the dies used in the machining process. Our quality control applications include defined inspection procedures administered throughout the production process and executed in a climate-controlled inspection room. MAM wants to partner with you from the beginning of your project to deliver parts that are machined to meet your tolerance and delivered on time.

We’ve been designing parts for decades. Let our experienced designers and drafters help you bring your idea to life.

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

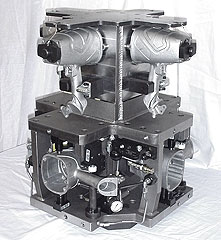

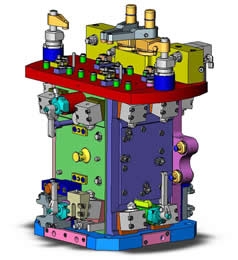

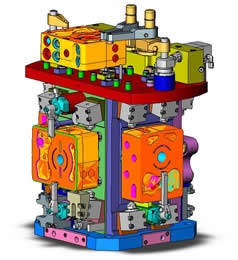

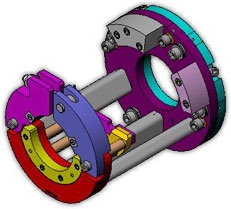

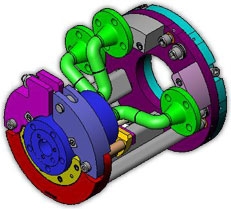

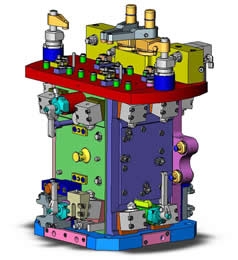

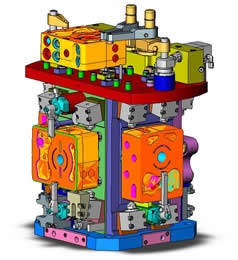

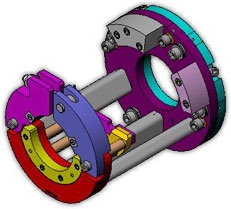

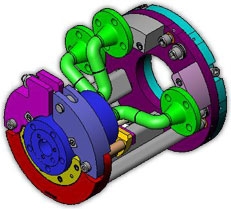

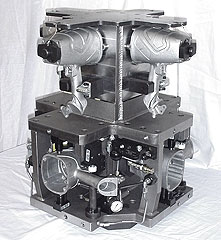

Mid-America Mfg. offered design services shortly after the company started back in 1995. Since then, we have designed a wide variety of gages, fixtures, jigs and other tooling items and we continue to do so today. We currently use two CAD packages, Solid Works and AutoCAD. The following pictures are a sample of some of the fixtures that we have designed and built.

We’ve been designing & building parts for decades. Let our experienced designers and machinists help you bring your idea to life.

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

From our beginning back in 1995, Mid-America Manufacturing has and continues to design a wide variety of gages, fixtures, jigs and other tooling items with the goal to deliver solutions that save time and money while ensuring accuracy and repeatability. Our design engineers utilize Solid Works and AutoCAD to develop and test solutions that meet your goals on time and within budget.

But we don’t stop with just design and engineering. MAM offers a turn-key approach that includes building your Jigs and Fixtures. Our workforce of talented machinist have a combined experience of over 100 years to apply to your specific requirements. We understand how design and fabrication need to work together to give you reliable, safe, and affordable solutions to support your manufacturing processes. Our complete solutions approach is what sets us apart from other machine shops.

Improve overall product quality, by implementing our dry vacuum-pressure impregnation process. You can enhance the quality and durability of your parts, ultimately boosting customer satisfaction and reducing returns.

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

MAM maintains a dry vacuum-pressure impregnation process to support our machining of gear pump parts. Casting Impregnation is the process of filling the pores of porous aluminum die-castings with a sealant under pressure to stop fluids or gases from leaking under pressure. Having the capability and equipment to apply this process in-house is a great advantage to MAM’s customers however, we offer this same impregnation process to anyone that has parts such as cylinder heads, cylinder blocks, brake systems, compressors and other parts that need to be leak proof. Casting Impregnation stops casting porosity and allows manufacturers to use parts that would otherwise be scrapped.

Added in 2015, our Hydrostatic Testing Process ensures your part is leak free, and ready for pressure-tight applications.

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

Hydrostatic testing is used to test the integrity of a material used in parts such as machined components, piping systems, gas cylinders and other kinds of pressure vessels. It is much less expensive to test the integrity of a part at the time it is manufactured as opposed to having a part fail after installation is complete. For that reason, many years ago Mid-America invested in a Barbee Hydro Tester that is capable of hydrostatic shell testing at fluid pressures up to 10,000 PSI for no-leak verification of machined components for pressure tight applications. It has a 100-Ton clamping force and is capable of testing components as large as 24”W x 20”H x 12”D. MAM applies hydrostatic testing to several machined components that we make as well as offering this service to customers with parts that we did not make. Contact us to find how we can help with your quality control needs!

We’ve been designing parts for decades. Let our experienced designers and drafters help you bring your idea to life.

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

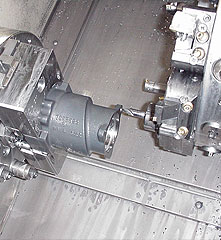

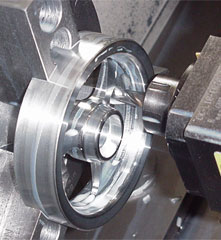

At Mid-America Manufacturing, we leverage cutting-edge CNC milling technology to deliver precision-engineered components that meet the highest standards of quality and performance. Our state-of-the-art facilities, combined with decades of industry expertise, enable us to produce complex parts with unmatched accuracy and efficiency. Whether you require prototyping, small-batch production, or high-volume manufacturing, our CNC milling services are tailored to meet your specific needs, ensuring optimal results every time.

Mid-America Mfg. is equipped with the following CNC Mills to meet your production needs:

We’ve been designing parts for decades. Let our experienced designers and drafters help you bring your idea to life.

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

At Mid-America Manufacturing, we leverage cutting-edge CNC turning technology to deliver precision-engineered components that meet the highest standards of quality and performance. Our state-of-the-art facilities, combined with decades of industry expertise, enable us to produce complex parts with unmatched accuracy and efficiency. Whether you require prototyping, small-batch production, or high-volume manufacturing, our CNC turning services are tailored to meet your specific needs, ensuring optimal results every time.

Mid-America Mfg. is equipped with the following CNC lathes for all your turning applications:

MAM has become a valuable resource for many when it comes to providing specialized machining services. These services include the following:

Explore manufacturing possibilities for your business today. Start with a quote and speak with one of our representatives to learn more.

This process is mainly for one-time needs or temporary off-load machining. We can often assist customers through times of crisis or unusual situations.

Prototype machining for your verification of new product designs or product changes. We understand the need for quality parts per the design requirements at a minimum price and lead-time. We have an intuitive sense of your needs and find a creative approach to satisfy them.

We offer machining for the parts that no longer fit your manufacturing environment, yet still have demands as replacement parts.

© Copyright Mid-America Manufacturing, LLC 2024. All Rights Reserved. | Privacy Policy

ISO 9001:2015 | Est. 1995

Web Design and Development by Saltech Systems

Offering custom machining services since 1995.